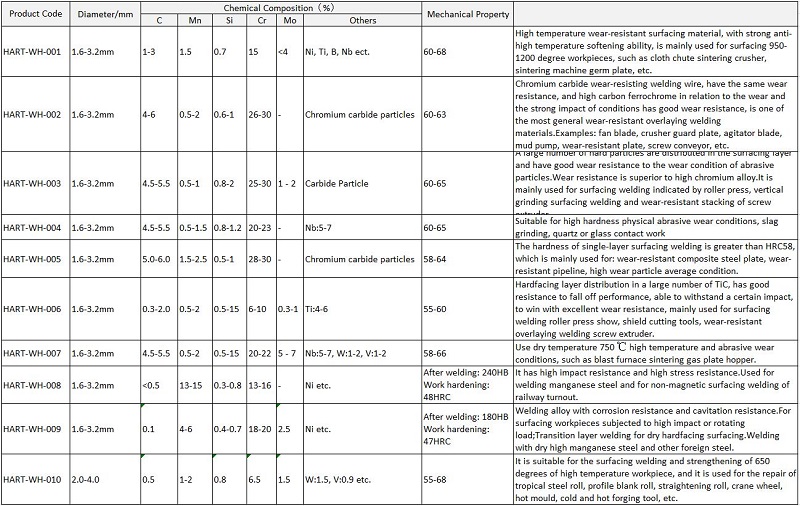

Other factors to consider about both gas-shielded and self-shielded flux-cored wires are their slag systems, which are classified as either rutile (T-1) or basic (T-5). See Figure 1 for other flux-cored wire classifications and operating specifications. Self-shielded flux-cored wires, again, do not require an external shielding gas supply. Using CO 2,offers good penetration, but may create more spatter and a less stable arc a mixture of argon/CO 2,provides good arc quality and lower spatter levels, but typically provides less penetration. Gas-shielded flux-cored wires require either pure CO 2, as in the previous example, or a mixture of argon/CO 2,(indicated by an M at the end of the classification). C designates that the product is to be used with 100 percent CO 2,shielding gas only.1 indicates the wire's usability and performance capabilities, including its operating parameters.T signifies a tubular (flux-cored) wire.0 indicates flat and horizontal positions (1 would imply a wire has all-position welding capabilities).7 indicates tensile strength (here, 70,000 pounds per square inch ).Note that hardsurfacing wires do not have a classification according to the American Welding Society (AWS), but all other gas- and self-shielded flux-cored wires do.Īs an example, a gas-shielded flux-cored wire designed for welding mild steel has the AWS classification E70T-1C. Flux-cored wires also are available for hardsurfacing new parts to protect them from impact and abrasion and for rebuilding old or worn-out parts. Gas-shielded and self-shielded flux-cored wires are available for flat/horizontal or all-position welding on base materials ranging from mild and low-alloy steel to stainless steel and special alloyed metals like chrome-moly.

Common applications for gas-shielded flux-cored wires include general fabrication, pressure vessels, petrochemical piping, and heavy-equipment manufacturing.

#FLUX CORE WIRE SIZE CHART PORTABLE#

The flux in self-shielded wires generates the shielding gas, which makes these wires highly portable and ideal for outdoor welding applications, such as structural steel, shipbuilding, and bridge construction. Both types are composed of an outer sheath and are filled with flux, a compound that is a mixture of alloys and deoxidizers, the latter of which are necessary to protect the weld from contaminants.Īs their name implies, gas-shielded flux-cored wires require an external shielding gas supply to protect the weld self-shielded wires do not. With more knowledge you can choose and use flux-cored wires confidently for your own welding applications.įlux-cored wires have been around since the 1950s and are available in two main versions: gas-shielded and self-shielded. Becoming acquainted with some basics, including the most appropriate applications, general classifications and characteristics, and advantages and limitations, of flux-cored wires can yield significant results. By arming yourself with some basic knowledge, you can choose and use flux-cored wires for your own welding applications confidently.įlux-cored arc welding (FCAW) wires certainly aren't new, but like any part of the welding process, understanding them can be confusing-without the right information.

0 kommentar(er)

0 kommentar(er)